Processing mechanical components in Vietnam

Machine parts are small but very important parts that form a complete modern machinery system. Machining of machine parts is also developed according to the development of science and technology. Therefore, to achieve professional improvements in machining methods, it is necessary to upgrade the technological process of machining machine parts.

Is the process of cutting the shape of machine parts from rough billet into finished product with precise size and structure. In this process, surface processing is the most important because it requires meticulousness and the quality of the finished product must be smooth and durable.

The same type of raw material but with different processes and modes will create finished products with different surface qualities and different usability properties. Surface quality is evaluated according to the criteria of geometric characteristics of the surface such as roughness, waviness, errors and criteria of physical and mechanical properties of the surface such as hardness, residual stress, surface layer structure.

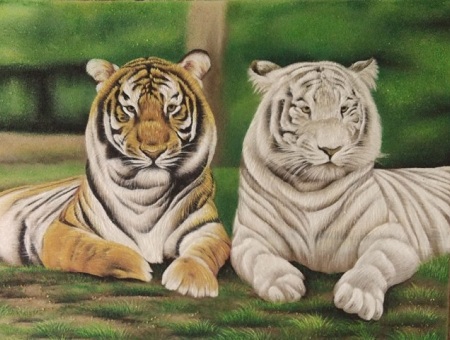

Processing mechanical components

I. Application for processing machine parts:

- Helps make the process of machining machine parts extremely easy and more productive

- Produce products with extremely high precision

- Helps save a lot of time and effort compared to traditional processing.

- The technology of using machines to process metal does not require workers to have high cutting skills as before but requires a higher level of mechanical knowledge, how to operate machines and tools. cutting, requires a huge amount of knowledge.

II. Machining process of machine details:

- Product design drawings: View and study detailed drawings, learn the purpose of use and detailed classification, technical requirements and technological characteristics of machine parts.

- Type of production to be performed: Single production, mass production, mass production.

- Select embryos and embryo fabrication methods: Select embryos with appropriate size and embryo fabrication method.

- Type of production to be performed: Single production, mass production, mass production.

- Select embryos and embryo fabrication methods: Select embryos with appropriate size and embryo fabrication method.

- It is necessary to determine the order of steps, operations…, choose a jig diagram for each operation and come up with methods to carry out machining.

- Choose appropriate tools, equipment and fixtures because it determines the quality of the product.

- Determine processing methods for each stage and step in the process.

- Choose appropriate items for the necessary steps.

- Assign each step to workers or technicians.

- Conduct processing on machinery such as CNC,… 10. Check product quality upon completion.

We accept reputable machine parts processing: Intech Precision Mechanical is one of the businesses with reputable mechanical processing skills, high quality machine parts, and reasonable prices. We can produce components, details, equipment and machinery spare parts, and process products according to customer designs.

Processing mechanical components 2

III. The mechanical processing services we receive:

– SMT processing,

– Processing jig jigs

– CNC milling & turning

– Machining machine details

– CNC precision machining: turning, round grinding, flat grinding

– Wave solder pallets,…

IV. Reasons to choose mechanical processing with us

- Mechanical processing of a variety of materials: stainless steel processing, steel processing, plastic processing,…

- Ensure high accuracy, according to customers’ requirements

- Fast processing time, quality assurance

- Professional, enthusiastic and dedicated staff

- Good service quality, fast delivery, best price on the market

V. Contact us:

We assist you in manufacturing components or finding the right unit to solve your problemwe can process mechanical products according to customers’ requirements.

Please contact us: (+84) 966050788 (Zalo, Whatsapp, Viber..)

Or visite us:

Best regard

Hai